Our skills

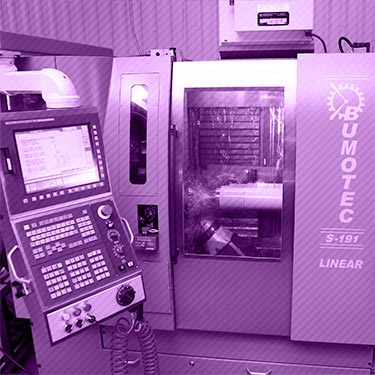

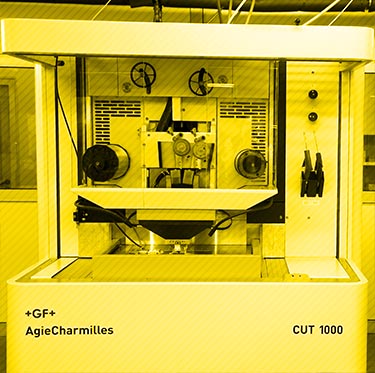

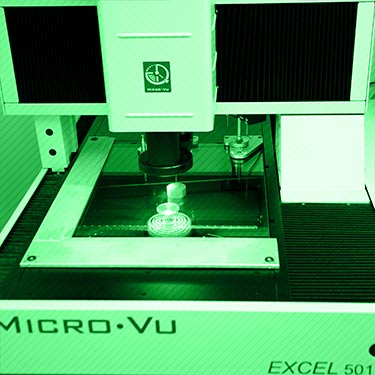

Tools

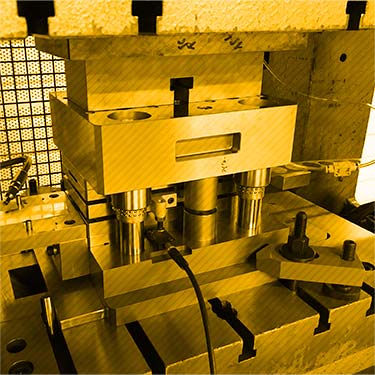

From design to production

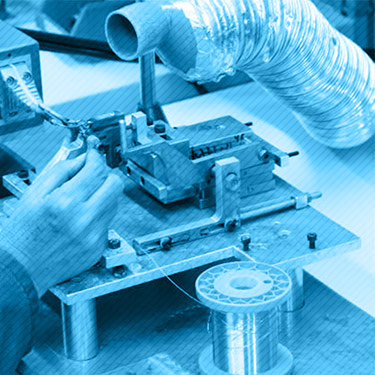

Design and production of press tools (cutting, stamping, folding). Design and production of progressive cutting tools for watchmaking, jewellery, or connectivity, for example. Design and realization of specific tooling for machining, polishing, assembly, welding, control...

- Manufacturing of mechanical components

- Assembly, adjustment

- Set up on our machines

- Production of pre-series on demand according to our customer’s request

Cutting / Stamping

30 years of experience in cold forming process

3 production workshops equipped with high speed automatic cutting presses, and hydraulic, pneumatic or mechanical presses from 10 to 300 t

- Atelier de presses horlogères

- Atelier de presses pour découpe bande de plus grandes dimensions

- Atelier de découpage / matriçage / pliage à froid

Steel, stainless steel, aluminum, bronze... We work all materials whose yield strength allows this type of process...

Mass finishing

Vibrator, centrifuge, barrel, drag finishing ... many processes available according to customer needs

This workshop specifically dedicated to the mass finishing allows to carry out operations of: degreasing, cleaning, deburring, descaling, shelving, deoxidation, shining or polishing parts.

Depending on the needs of abrasion and the materials to be treated (brass, nickel silver, steel, stainless steel, titanium, aluminum, bronze, niclafor, or plastic), we use different materials for finishing operations: plastic cones, porcelain, organic material, ceramic, copper...